Rule 3745-40-04 | Biosolids classifications.

[Comment: For dates of non-regulatory government publications, publications of recognized organizations and associations, federal rules and federal statutory provisions referenced in this rule, see rule 3745-40-01 of the Administrative Code.]

(A) General requirements.

(1) A biosolids classification shall be determined in accordance with table A-1 of this rule.

(a) For exceptional quality biosolids, the pathogen reduction alternatives in accordance with table A-1 of this rule shall be met either prior to or at the same time as meeting the vector attraction reduction requirements, except the vector attraction reduction requirements in paragraphs (C)(6) to (C)(8) of this rule.

| Biosolids classification | Requirements for pathogen reduction | Additional requirements for fecal coliform or Salmonella sp. bacteria reduction | Requirements for vector attraction reduction | Requirements for metals concentration limits |

| B | Choose from pathogen reduction alternatives P-1 to P-16, in accordance with paragraphs (B)(1) to (B)(16) of this rule | Not applicable. No additional requirements for fecal coliform exist beyond the requirements to meet pathogen reduction alternative P-1 | Choose from vector attraction reduction options VAR-1 to VAR-10, in accordance with paragraphs (C)(1) to (C)(10) of this rule | Table D-1 of this rule, and as applicable table D-3 of this rule |

| Exceptional quality | Choose from pathogen reduction alternatives P-8 to P-16, in accordance with paragraphs (B)(8) to (B)(16) of this rule | Applicable in accordance with paragraph (B) of this rule | Choose from vector attraction reduction options VAR-1 to VAR-8, in accordance with paragraphs (C)(1) to (C)(8) of this rule | Table D-1 of this rule and table D-3 of this rule |

.

(2) Records shall be kept in accordance with this rule and rule 3745-40-09 of the Administrative Code and maintained for as minimum of five years.

(B) Pathogen reduction alternatives.

Class B biosolids: For class B biosolids, pathogen reduction shall be accomplished in accordance with an alternative found in paragraphs (B)(l) to (B)(16) of this rule.

Exceptional quality biosolids: For exceptional quality biosolids, pathogen reduction shall be accomplished when the density of fecal coliform in the sewage sludge is less than one thousand most probable number (mpn) per gram of total solids (dry weight basis) or the density of Salmonella sp. bacteria in the sewage sludge is less than three most probable number (mpn) per four grams of total solids (dry weight basis), and a pathogen reduction alternative is accomplished in accordance with an alternative found in paragraphs (B)(8) to (B)(16) of this rule. The pathogen reduction alternative shall be met either prior to, or at the same time as meeting the vector attraction reduction requirement in paragraphs (C)(1) to (C)(8) of this rule. To meet the fecal coliform or Salmonella sp. bacteria requirement, the sampling results shall be representative of the biosolids leaving the treatment works. At a minimum, seven grab samples of the biosolids shall be taken and analyzed at least once per reporting period and all results shall meet the limits listed in this paragraph for the biosolids to be considered exceptional quality.

(1) Pathogen reduction alternative P-1: geometric mean of seven samples.

(a) Requirements for achieving pathogen reduction alternative P-1.

(i) At a minimum, seven grab samples of the sewage sludge that are proposed for authorized beneficial use shall be collected. The samples of the sewage sludge shall be taken at various locations, so as to be representative. The director may require more than seven samples to be taken to ensure adequate representation.

(ii) The geometric mean of the density of fecal coliform in the sewage sludge samples shall be either of the following:

(a) Less than two million most probable number (mpn) per gram of total solids (dry weight basis).

(b) Less than two million colony forming units (cfu) per gram of total solids (dry weight basis).

[Comment: Seven samples shall be taken over a two-week period or in accordance with the standard operating procedure developed under paragraph (C) of rule 3745-40-09 of the Administrative Code. Example calculations may be found in "Environmental Regulations and Technology - Control of Pathogens and Vector Attraction in Sewage Sludge."]

(b) Monitoring frequency requirements for pathogen reduction alternative P-1. The permittee shall complete monitoring in accordance with paragraphs (B)(1)(a) to (B)(1)(a)(ii) of rule 3745-40-04 of the Administrative Code and at the frequencies specified in paragraph (B) of rule 3745-40-09 of the Administrative Code.

(c) Record keeping requirements for pathogen reduction alternative P-1. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Written documentation that the sewage sludge has been stabilized through an actively mixed aerobic or anaerobic process or through lime stabilization. Examples of such documentation include documenting that lime has been added to the sewage sludge, that proper mixing and aeration has occurred or calculating the mean cell residence time in a digester.

(ii) Analytical results for density of fecal coliform for each sample collected from the sewage sludge.

(iii) The geometric mean calculations for the sewage sludge.

(2) Pathogen reduction alternative P-2: aerobic digestion.

(a) Requirements for achieving pathogen reduction alternative P-2: aerobic digestion. The requirements for achieving alternative P-2 include both of the following:

(i) The sewage sludge shall be agitated with air or oxygen to maintain aerobic conditions for a specific mean cell residence time at a specific temperature.

(ii) The values for the mean cell residence time and temperature shall be between forty days at twenty degrees Celsius (sixty-eight degrees Fahrenheit) and sixty days at fifteen degrees Celsius (fifty-nine degrees Fahrenheit), where a minimum temperature of fifteen degrees Celsius is maintained at all times.

[Comment: The relevant equation for the mean cell residence time and appurtenant information can be found in appendix E of "Environmental Regulations and Technology - Control of Pathogen and Vector Attraction in Sewage Sludge." To calculate the number of days of the mean cell residence time that is required for temperatures between fifteen and twenty degrees Celsius (between fifty-nine and sixty-eight degrees Fahrenheit), the following equation shall be used:

Time in days = 40 x 1.08 (20-T) (Where T is the temperature between fifteen and twenty degrees Celsius.) ]

(b) Recordkeeping requirements for pathogen reduction alternative P-2: aerobic digestion. Both of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) The mean cell residence time of the sewage sludge in each aerobic digester.

(ii) The records showing the proper temperature was maintained during the mean cell residence time.

(3) Pathogen reduction alternative P-3: air drying.

(a) Requirements for achieving pathogen reduction alternative P-3: air drying. The requirements for achieving alternative P-3 include all of the following:

(i) Partially digested sewage sludge is dried on sand beds or on paved or unpaved basins for a minimum of ninety days.

[Comment: Partially digested sewage sludge means sewage sludge that has been partially stabilized through either an aerobic or anaerobic process.]

(ii) The average ambient air temperature is greater than zero degrees Celsius (thirty-two degrees Fahrenheit) for at least sixty consecutive days within the ninety-day period.

(iii) The sewage sludge shall be exposed to the atmosphere for at least sixty consecutive days within the ninety-day period.

[Comment: When sewage sludge is covered by snow or being dewatered inside a geotextile bag, it is not considered to be exposed to the atmosphere.]

(iv) All leachate from the drying basins is returned to the treatment process.

(b) Recordkeeping requirements for pathogen reduction alternative P-3: air drying. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Written documentation that the sewage sludge has been partially stabilized through an aerobic or anaerobic process.

(ii) Written documentation that the sewage sludge has been stabilized through an actively mixed aerobic or anaerobic process.

(iii) A description of the drying bed design, including the type of media being used, the number of drying beds available, the number of drying beds in use, and the dimensions of each drying bed.

(iv) The drying time in days for each drying bed in use.

(v) The daily minimum temperature for each of the ninety days.

(4) Pathogen reduction alternative P-4: anaerobic digestion.

(a) Requirements to achieve pathogen reduction alternative P-4: anaerobic digestion. The requirements for achieving alternative P-4 include both of the following:

(i) Sewage sludge or biosolids shall be treated in the absence of air for a specific mean cell residence time at a specific temperature. The sewage sludge or biosolids may be commingled with bulking agents or additives, as defined in rule 3745-560-02 of the Administrative Code, and feedstocks. Bulking agents, additives, or feedstocks shall be introduced prior to, or during the anaerobic digestion process. An alternative feedstock shall be authorized by the director or an authorized representative in accordance with rule 3745-40-02 of the Administrative Code.

(ii) The values for the mean cell residence time and the temperature shall be between fifteen days at thirty-five to fifty-five degrees Celsius (between ninety-five and one hundred thirty-one degrees Fahrenheit) and sixty days at twenty degrees Celsius (sixty-eight degrees Fahrenheit). A minimum temperature of twenty degrees Celsius (sixty-eight degrees Fahrenheit) shall be maintained at all times.

[Comment: The relevant equations for the mean cell residence time and appurtenant information can be found in appendix E of "Environmental Regulations and Technology-Control of Pathogen and Vector Attraction in Sewage Sludge." To calculate the number of days of the mean cell residence time required for temperatures between twenty and thirty degrees Celsius (between sixty-eight and ninety-five degrees Fahrenheit), the following equation should be used:

Time in days = 15+3 (35-T) (Where T is the temperature between twenty and thirty-five degrees Celsius.)]

(b) Recordkeeping requirements for pathogen reduction alternative P-4: anaerobic digestion. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) The mean cell residence time of sewage sludge in each digester.

(ii) The temperature records of sewage sludge in each digester.

(iii) The weight or volume and general counties of origin of all feedstocks, bulking agents and additives utilized in the anaerobic digestion process.

(5) Pathogen reduction alternative P-5: class B composting.

(a) Requirements for achieving pathogen reduction alternative P-5: class B composting. The requirements for achieving alternative P-5 include both of the following:

(i) Operating in accordance with the requirements of Chapters 3704. and 6111. of the Revised Code, section 3745.11 of the Revised Code and rules adopted there under. Such treatment works shall not be subject to the requirements in Chapter 3745-560 of the Administrative Code if all of the following conditions are met:

(a) The owner or operator of the treatment works is operating the treatment works in accordance with an NPDES permit issued in accordance with Chapter 6111. of the Revised Code.

(b) The owner or operator of the treatment works composts sewage sludge or biosolids exclusively with bulking agents or additives, as defined in rule 3745-560-02 of the Administrative Code.

(c) The owner or operator of the treatment works utilizes only sewage sludge, biosolids, yard waste, animal waste, food scraps, food waste or an alternative feedstock that has been approved by the director or an authorized representative as feedstocks in the composting process.

(ii) Composting that is accomplished through any of the following:

(a) In vessel composting, where all of the following apply:

(i) The temperature of the compost medium is maintained at forty degrees Celsius (one hundred four degrees Fahrenheit) or higher for five consecutive days throughout the entire composting medium.

(ii) For four consecutive hours during the five-day period, the temperature of the composting medium must rise above fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit).

(iii) The temperature is measured at multiple points and at a range of depths throughout the composting medium and shall be recorded at the beginning of the compost process when the minimum temperature has been reached, at least once daily, at least once per hour during the four-hour period when the composting medium is above fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) and at the end of the five-day period.

(b) Aerated static pile composting, where all of the following apply:

(i) The temperature of the composting medium is maintained at forty degrees Celsius (one hundred four degrees Fahrenheit) or higher for five consecutive days throughout the entire composting medium.

(ii) For four consecutive hours during the five-day period, the temperature of the composting medium must rise above fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit).

(iii) One foot or greater of an insulation material shall be placed over the surface of the aerated static pile to ensure that the entire composting medium achieves forty degrees Celsius (one hundred four degrees Fahrenheit) or higher. Finished compost used as insulation material to cover the aerated static pile must be exceptional quality biosolids .

(iv) The temperature is measured at multiple points and at a range of depths throughout the composting medium, including the toes of the pile, and shall be recorded at the beginning of the composting process, at least once daily, at least once per hour during the four-hour period that the composting medium is above fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) and at the end of the five-day period.

[Comment: It is recommended that a method be used that draws air through the composting medium rather than blowing air through the medium. Drawing air through the composting medium provides greater odor control because the compost air can be easily collected and then filtered or scrubbed.]

(c) Windrow composting, where all of the following apply:

(i) The temperature of the windrow of composting medium shall be maintained at forty degrees Celsius (one hundred four degrees Fahrenheit) or higher for a minimum of five consecutive days, except during active turning or mixing of the windrow.

(ii) For four consecutive hours during the five-day period, the temperature of the composting medium must rise above fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit).

(iii) The windrow of composting medium shall be turned or mixed during the five-day period so that the entire compost medium has maintained a temperature of forty degrees Celsius (one hundred four degrees Fahrenheit) for a minimum of five days. The turning or mixing shall be done by a machine that moves the core of the composting material to the outside of the windrow and moves the outside compost material into the core of the windrow.

(iv) The temperature of the windrow shall be at or above forty degrees Celsius (one hundred four degrees Fahrenheit) within twenty-four hours after the turning or mixing of the windrow is complete.

(v) The temperature is measured at multiple points and at a range of depths throughout the composting medium, including the toes of the pile, and shall be recorded at the beginning of the composting process, at least once daily, at least once per hour during the four-hour period that the composting medium is above fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) and at the end of the five-day period.

[Comment: It is recommended that treatment works allow sewage sludge or biosolids to compost for a minimum of fourteen days for in-vessel composting, twenty-one days for static aerated pile composting, or thirty days for windrow composting to reduce volatile solids in the sewage sludge or biosolids. Sewage sludge or biosolids that are composted for the minimum amount of time by rule may still be odorous. Composting is generally considered complete when the temperature of the compost returns to ambient temperatures.]

(b) Recordkeeping requirements for pathogen reduction alternative P-5: composting. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) A description of the composting method, including where the temperature shall be measured.

(ii) The weight or volume and general counties of origin of all feedstocks, bulking agents and additives utilized in the composting process.

(iii) For in-vessel composting, both of the following:

(a) The daily temperature records for each vessel at each sample location that documents that the sewage sludge was maintained at a temperature of forty degrees Celsius (one hundred four degrees Fahrenheit) for five days.

(b) The hourly readings for each vessel at each sample location showing that the temperature exceeded fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) for four consecutive hours.

(iv) For aerated static pile composting, both of the following:

(a) The daily temperature records for each aerated static pile at each sample location that documents that the sewage sludge was maintained at a temperature of forty degrees Celsius (one hundred four degrees Fahrenheit) for five days.

(b) The hourly readings for each aerated static pile at each sample location showing that the temperature exceeded fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) for four consecutive hours.

(v) For windrow composting, all of the following:

(a) The daily temperature records for each windrow at each sample location that documents that the sewage sludge was maintained at a temperature of forty degrees Celsius (one hundred four degrees Fahrenheit) for five days.

(b) Hourly readings for each windrow at each sample location showing that the temperature exceeded fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) for four consecutive hours.

(c) Records that indicate the day and the time of day each windrow was turned or mixed.

(6) Pathogen reduction alternative P-6: lime treatment.

(a) Requirements for achieving pathogen reduction alternative P-6: lime treatment. The requirements for achieving alternative P-6 include all of the following:

(i) Adding sufficient lime to the sewage sludge to raise the pH to twelve after two hours of contact.

(ii) Sufficient mixing to ensure that the entire mass of sewage sludge comes into contact with the lime and achieves the minimum pH of twelve. The pH shall be measured at several locations to ensure that the pH is raised throughout the sewage sludge.

(iii) Utilizing best management procedures to minimize odors.

(b) Recordkeeping requirements for pathogen reduction alternative P-6: lime treatment. Records shall be maintained and submitted to the director or an authorized representative with the annual report that include all of the following:

(i) A description of how the pH is monitored throughout the sewage sludge and how the lime is mixed into the sewage sludge.

(ii) Records that initially document the pH of the sewage sludge once lime has been added and then documents the pH again two hours after the addition of the lime.

(iii) Records showing the amount of lime material that was added and when it was added, expressed in dry tons.

[Comment: A variety of lime stabilization processes are currently in use. The effectiveness of any lime stabilization process for controlling pathogens depends on maintaining the pH at levels that reduce microorganisms in the sewage sludge. Field experience has shown that the authorized beneficial use of lime stabilized material after the pH has dropped below 10.5 may, in some cases, create odor problems. Therefore, it is recommended that biosolids beneficial use take place while the pH remains elevated. If this is not possible, and odor problems develop, alternate management practices in the field, including injection or incorporation or top dressing the beneficially used biosolids with additional lime, shall be performed. Alternate management practices, if the biosolids have not yet left the treatment works, may include adding additional lime to maintain the elevated pH or additional treatment through drying or composting.]

(7) Pathogen reduction alternative P-7: equivalent process to significantly reduce pathogens.

(a) Requirements for achieving pathogen reduction alternative P-7: equivalent process to significantly reduce pathogens. To achieve alternative P-7, sewage sludge that will be treated to generate biosolids for beneficial use shall be treated in a process that is equivalent to a process to significantly reduce pathogens, as determined by the director.

(b) Recordkeeping requirements for pathogen reduction alternative P-7: equivalent process to significantly reduce pathogens. The records of the operating parameters or pathogen levels, as necessary to demonstrate the process equivalent to a process to significantly reduce pathogens, shall be maintained and submitted to the director or an authorized representative with the annual report.

(8) Pathogen reduction alternative P-8: time and temperature regime.

(a) Requirements for achieving pathogen reduction alternative P-8: time and temperature regime. The requirements for achieving alternative P-8 include maintaining a temperature in the sewage sludge at a specific value for a specific time period, in accordance with the following:

(i) When the per cent solids of the sewage sludge is seven per cent or higher, the temperature of the sewage sludge shall be fifty degrees Celsius (one hundred twenty-two degrees Fahrenheit) or higher, the time period shall be twenty minutes or longer and the temperature and time period shall be determined using equation number one, except when small particles of sewage sludge are heated by either warmed gases or an immiscible liquid. Equation number one is as follows:

D = 131,700,000/100.1400T (where D equals time in days and T equals temperature in degrees Celsius).

[Comment: The times and temperatures in table B-1 of this rule provide common durations for common temperatures, relevant to the requirements of paragraph (B)(8)(a)(i) of this rule.]

| Temperature in degrees Celsius | Temperature in degrees Fahrenheit | Duration in days | Duration in hours | Duration in minutes |

| 50 | 122 | 14 | -- | -- |

| 52 | 125.6 | 7 | -- | -- |

| 54 | 129.2 | 4 | -- | -- |

| 56 | 132.8 | 2 | -- | -- |

| 58 | 136.4 | -- | 24 | -- |

| 60 | 140 | -- | 13 | -- |

| 62 | 143.6 | -- | 7 | -- |

| 64 | 147.2 | -- | 4 | -- |

| 66 | 150.8 | -- | 2 | -- |

| 68 | 154.4 | -- | -- | 57 |

| 70 | 158 | -- | -- | 30 |

| 72 | 161.6 | -- | -- | 20 |

| 74 | 165.2 | -- | -- | 20 |

| 76 | 168.8 | -- | -- | 20 |

| 78 | 172.4 | -- | -- | 20 |

| 80 | 176 | -- | -- | 20 |

| 82 | 179.6 | -- | -- | 20 |

| 84 | 183.2 | -- | -- | 20 |

| Above 84 | Above 183.2 | -- | -- | 20 |

(ii) When the per cent solids of the sewage sludge is seven per cent or higher and small particles of sewage sludge are heated by either warmed gases or an immiscible liquid, the temperature of the sewage sludge shall be fifty degrees Celsius (one hundred twenty-two degrees Fahrenheit) or higher, the time period shall be fifteen seconds or longer and the temperature and time period shall be determined using equation number one.

[Comment: The times and temperatures in table B-2 of this rule provide common durations for common temperatures, relevant to the requirements of paragraph (B)(8)(a)(ii) of this rule.]

| Temperature in degrees Celsius | Temperature in degrees Fahrenheit | Duration in days | Duration in hours | Duration in minutes | Duration in seconds |

| 50 | 122 | 14 | -- | -- | -- |

| 52 | 125.6 | 7 | -- | -- | -- |

| 54 | 129.2 | 4 | -- | -- | -- |

| 56 | 132.8 | 2 | -- | -- | -- |

| 58 | 136.4 | 1 | -- | -- | -- |

| 60 | 140 | -- | 13 | -- | -- |

| 62 | 143.6 | -- | 7 | -- | -- |

| 64 | 147.2 | -- | 4 | -- | -- |

| 66 | 150.8 | -- | 2 | -- | -- |

| 68 | 154.4 | -- | -- | 57 | -- |

| 70 | 158 | -- | -- | 30 | -- |

| 72 | 161.6 | -- | -- | 16 | -- |

| 74 | 165.2 | -- | -- | 9 | -- |

| 76 | 168.8 | -- | -- | 5 | -- |

| 78 | 172.4 | -- | -- | 3 | -- |

| 80 | 176 | -- | -- | 2 | -- |

| 82 | 179.6 | -- | -- | -- | 38 |

| 84 | 183.2 | -- | -- | -- | 20 |

| Above 84 | Above 183.2 | -- | -- | -- | 15 |

(iii) When the per cent solids of the sewage sludge is less than seven per cent and the time period is at least fifteen seconds, but less than thirty minutes, the temperature and time period shall be determined using equation number one.

[Comment: Times and temperatures in table B-3 of this rule provide common durations for common temperatures, relevant to the requirements of paragraph (B)(8)(a)(iii) of this rule.]

| Temperature in degrees Celsius | Temperature in degrees Fahrenheit | Duration in days | Duration in hours | Duration in minutes | Duration in seconds |

| 70 | 158 | -- | -- | 30 | -- |

| 72 | 161.6 | -- | -- | 15 | -- |

| 74 | 165.2 | -- | -- | 9 | -- |

| 76 | 168.8 | -- | -- | 5 | -- |

| 78 | 172.4 | -- | -- | 3 | -- |

| 80 | 176 | -- | -- | 2 | -- |

| 82 | 179.6 | -- | -- | -- | 38 |

| 84 | 183.2 | -- | -- | -- | 20 |

| Above 84 | Above 183.2 | -- | -- | -- | 15 |

(iv) When the per cent solids of the sewage sludge is less than seven per cent, the temperature of the sewage sludge is fifty degrees Celsius (one hundred twenty-two degrees Fahrenheit) or higher, and the time period is thirty minutes or longer, the temperature and time period shall be determined using equation number two. Equation number two is as follows:

D = 50,070,000/100.1400T (Where D equals time in days and T equals temperature in degrees Celsius.)

[Comment: The times and temperatures in table B-4 of this rule provide common durations for common temperatures, relevant to the requirements in paragraph (B)(8)(a)(iv) of this rule.]

| Temperature in degrees Celsius | Temperature in degrees Fahrenheit | Duration in days | Duration in hours | Duration in minutes |

| 50 | 122 | 5 | -- | -- |

| 52 | 125.6 | 3 | -- | -- |

| 54 | 129.2 | 2 | -- | -- |

| 56 | 132.8 | -- | 18 | -- |

| 58 | 136.4 | -- | 10 | -- |

| 60 | 140 | -- | 5 | -- |

| 62 | 143.6 | -- | 3 | -- |

| 64 | 147.2 | -- | 2 | -- |

| 66 | 150.8 | -- | -- | 42 |

| 68 | 154.4 | -- | -- | 30 |

| 70 | 158 | -- | -- | 30 |

| 72 | 161.6 | -- | -- | 30 |

| 74 | 165.2 | -- | -- | 30 |

| 76 | 168.8 | -- | -- | 30 |

| 78 | 172.4 | -- | -- | 30 |

| 80 | 176 | -- | -- | 30 |

| 82 | 179.6 | -- | -- | 30 |

| 84 | 183.2 | -- | -- | 30 |

| Above 84 | Above 183.2 | -- | -- | 30 |

(b) Recordkeeping requirements for pathogen reduction alternative P-8: time and temperature regime. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Analytical results for density of fecal coliform bacteria expressed as the most probable number (mpn) per gram of total solids in dry weight basis, or the density of Salmonella sp. bacteria expressed as mpn per four grams of total solids in dry weight basis.

(ii) The sewage sludge temperature.

(iii) The duration, in days, hours, minutes and seconds, as applicable, that the temperature was maintained.

(iv) Analytical results for per cent solids of the sewage sludge or biosolids treated in the process.

(9) Pathogen reduction alternative P-9: high pH and high temperature process.

(a) Requirements for achieving pathogen reduction alternative P-9: high pH and high temperature process. The requirements for achieving alternative P-9 include all of the following:

(i) Ensuring that the pH of the sewage sludge is raised to above twelve and remains above twelve for at least seventy-two hours.

(ii) Sufficient mixing to ensure that the entire mass of sewage sludge comes into contact with the lime and achieves the minimum pH of twelve. The pH shall be measured at several locations to ensure that the pH is raised throughout the sewage sludge.

(iii) Ensuring that the temperature of the sewage sludge is above fifty-two degrees Celsius (one hundred twenty-five and six tenths degrees Fahrenheit) for at least twelve hours during the period that the pH is above twelve.

(iv) Ensuring that at the end of the seventy-two-hour period during which the pH of the sewage sludge is above twelve, that the sewage sludge is air dried to a per cent solids of greater than fifty per cent.

(b) Recordkeeping requirements for pathogen reduction alternative P-9: high pH and high temperature process. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Analytical results for density of fecal coliform bacteria expressed as the most probable number (mpn) per gram of total solids in dry weight basis, or the density of Salmonella sp. bacteria expressed as mpn per four grams of total solids in dry weight basis.

(ii) Records of the sewage sludge pH at start-up, at twenty-four hours, at forty-eight hours and at seventy-two hours.

(iii) The hourly sewage sludge temperature for the twelve hours that the temperature is required to be maintained.

(iv) The per cent solids of the sewage sludge after air drying.

(v) Records showing the amount of lime material that was added and when it was added, expressed in dry tons.

(vi) A description of how the pH and temperature are maintained throughout the sewage sludge.

(10) Pathogen reduction alternative P-10: exceptional quality composting.

(a) Requirements for achieving pathogen reduction alternative P-10: exceptional quality composting. The requirements for achieving alternative P-10 include the following:

(i) Operating in accordance with the requirements of Chapters 3704. and 6111. of the Revised Code, section 3745.11 of the Revised Code and any rules adopted there under. Such treatment works is not subject to the requirements of Chapter 3745-560 of the Administrative Code if all the following conditions are met:

(a) The owner or operator of the treatment works is operating the treatment works in accordance with an NPDES permit issued in accordance with Chapter 6111. of the Revised Code.

(b) The owner or operator of the treatment works co-composts sewage sludge or biosolids exclusively with bulking agents or additives, as defined in rule 3745-560-02 of the Administrative Code, or alternative bulking agents or additives that have been approved by the director or an authorized representative.

(c) The owner or operator of the treatment works utilizes only sewage sludge, biosolids, animal waste, food scraps, food waste or an alternative feedstock that has been approved by the director or an authorized representative as feedstocks in the composting process.

(ii) Composting that is accomplished through any of the following methods:

(a) In-vessel composting, where both of the following conditions are met:

(i) The temperature of the composting medium is maintained at fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) or higher for seventy-two hours throughout the entire composting medium.

(ii) The temperature is measured at multiple points and at a range of depths throughout the composting medium and shall be recorded, at a minimum, at the beginning of the composting process, at twenty-four hours, at forty-eight hours and at seventy-two hours.

(b) Aerated static pile composting, where all of the following conditions are met:

(i) The temperature of the composting medium is maintained at fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) or higher for seventy-two consecutive hours throughout the entire composting medium.

(ii) One foot or greater of an insulation material is placed over the surface of the aerated static pile to help ensure that the entire composting medium achieves fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) or higher. Finished compost can be used as an insulation material to cover the aerated static pile provided it is exceptional quality biosolids.

(iii) The temperature is measured at multiple points and at a range of depths throughout the composting medium including the toes of the piles, and is recorded, at a minimum, at the beginning of the composting process and at twenty-four, forty-eight and seventy-two hours at a minimum.

[Comment: It is recommended that a method be used that draws air through the composting medium rather than blowing air through the medium. Drawing air through the composting medium provides greater odor control because the air can be easily collected and then filtered or scrubbed.]

(c) Windrow composting, where all of the following conditions are met:

(i) The temperature of the composting medium is maintained at fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) or higher for a minimum of fifteen consecutive days, except during active turning or mixing of the windrow.

(ii) The windrow of composting medium is turned or mixed at seventy-two hour intervals during the fifteen-day period, where the minimum number of turnings or mixings is five.

(iii) The turning or mixing is done by a machine that moves the core of the compost material to the outside of the windrow and moves the outside compost material into the core of the windrow.

(iv) The core temperature of the windrow is at or above fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) within twenty-four hours after each turning or mixing of the windrow is complete.

(v) The temperature shall be measured in the core of the windrow at various locations along the length of the windrow. Temperatures shall be recorded at the same time daily, at a minimum, throughout the fifteen-day period.

[Comment: To reduce volatile solids, it is recommended that in-vessel composting be conducted for a minimum of fourteen days, that static, aerated pile composting be conducted for a minimum of twenty-one days and that windrow composting be conducted for a minimum of thirty days. Sewage sludge or biosolids that are composted for the minimum amount of times may still be odorous.]

(b) Recordkeeping requirements for pathogen reduction alternative P-10: composting. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Analytical results for density of fecal coliform bacteria expressed as the most probable number (mpn) per gram of total solids in dry weight basis, or the density of Salmonella sp. bacteria expressed as mpn per four grams of total solids in dry weight basis.

(ii) A description of the composting method, including where the temperature was measured.

(iii) The weight or volume and general counties of origin of all feedstocks, bulking agents and additives utilized in the composting process.

(iv) Records documenting the temperature maintained at or above fifty-five degrees Celsius (one hundred thirty-one degrees Fahrenheit) for each sampling location:

(a) Three days for either in-vessel or static, aerated pile composting.

(b) Fifteen days for windrow composting.

(v) If windrow composting was utilized, both of the following:

(a) Records documenting the compost pile was turned or mixed at least five times during the fifteen-day period.

(b) Records that indicate the day and the time of day each windrow was turned or mixed.

(11) Pathogen reduction alternative P-11: heat drying.

(a) Requirements for achieving pathogen reduction alternative P-11: heat drying. The requirements for achieving alternative P-11 include drying the sewage sludge by direct or indirect contact with hot gases to increase the sewage sludge to a per cent solids content of at least ninety per cent, where either the temperature of the sewage sludge particles exceeds eighty degrees Celsius (one hundred seventy-six degrees Fahrenheit) or the wet bulb temperature of the gas in contact with the sewage sludge as the sewage sludge leaves the dryer exceeds eighty degrees Celsius (one hundred seventy-six degrees Fahrenheit).

(b) Recordkeeping requirements for pathogen reduction alternative P-11: heat drying. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Analytical results for density of fecal coliform bacteria expressed as the most probable number (mpn) per gram of total solids in dry weight basis, or the density of Salmonella sp. bacteria expressed as mpn per four grams of total solids in dry weight basis.

(ii) The per cent solids of the dried sewage sludge.

(iii) Records documenting that the temperature of the sewage sludge particles or the wet bulb temperature of exit gas exceeds eighty degrees Celsius (one hundred seventy-six degrees Fahrenheit).

(12) Pathogen reduction alternative P-12: thermophilic aerobic digestion.

(a) Requirements for achieving pathogen reduction alternative P-12: thermophilic aerobic digestion. The requirements for achieving alternative P-12 include agitating the liquid sewage sludge with air or oxygen to maintain aerobic conditions, where the mean cell residence time is ten days and the temperature, which is measured at least once per day, is between fifty-five and sixty degrees Celsius (one hundred thirty-one degrees to one hundred forty degrees Fahrenheit).

(b) Recordkeeping requirements for pathogen reduction alternative P-12: thermophilic aerobic digestion. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Analytical results for density of fecal coliform bacteria expressed as the most probable number (mpn) per gram of total solids in dry weight basis, or the density of Salmonella sp. bacteria expressed as mpn per four grams of total solids in dry weight basis.

(ii) Records documenting the temperature was maintained at fifty-five to sixty degrees Celsius (one hundred thirty-one degrees to one hundred forty degrees Fahrenheit) in each digester.

(iii) Records documenting the mean cell residence time was met in each digester.

(13) Pathogen reduction alternative P-13: beta ray irradiation.

(a) Requirements for achieving pathogen reduction alternative P-13: beta ray irradiation. To achieve alternative P-13, the sewage sludge shall be irradiated with beta rays from an accelerator at dosages of at least one megarad at room temperature (approximately twenty degrees Celsius or sixty-eight degrees Fahrenheit).

(b) Recordkeeping requirements for pathogen reduction alternative P-13: beta ray irradiation. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Analytical results for density of fecal coliform bacteria expressed as the most probable number (mpn) per gram of total solids in dry weight basis, or the density of Salmonella sp. bacteria expressed as mpn per four grams of total solids in dry weight basis.

(ii) The beta ray dosage.

(iii) The ambient room temperature records.

(14) Pathogen reduction alternative P-14: gamma ray irradiation.

(a) Requirements for achieving pathogen reduction alternative P-14: gamma ray irradiation. To achieve alternative P-14, the sewage sludge shall be irradiated with gamma rays from certain isotopes, such as \60\cobalt and \137\cesium, at dosages of at least one megarad at room temperature (approximately twenty degrees Celsius or sixty-eight degrees Fahrenheit).

(b) Recordkeeping requirements for pathogen reduction alternative P-14: gamma ray irradiation. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Documentation of the gamma ray isotope uses.

(ii) The gamma ray dosage.

(iii) Ambient room temperature records.

(iv) Analytical results for density of fecal coliform bacteria expressed as the most probable number (mpn) per gram of total solids in dry weight basis, or the density of Salmonella sp. bacteria expressed as mpn per four grams of total solids in dry weight basis.

(15) Pathogen reduction alternative P-15: pasteurization.

(a) Requirements for achieving pathogen reduction alternative P-15: pasteurization. To achieve alternative P-15, the temperature of the sewage sludge shall be maintained at seventy degrees Celsius (one hundred fifty-eight degrees Fahrenheit) or higher for thirty minutes or longer. A device shall be used to monitor the temperatures to ensure that the temperature of the sewage sludge does not fall below seventy degrees Celsius (one hundred fifty-eight degrees Fahrenheit) during the thirty-minute period.

(b) Recordkeeping requirements for alternative P-15: pasteurization. Both of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Analytical results for density of fecal coliform bacteria expressed as the most probable number (mpn) per gram of total solids in dry weight basis, or the density of Salmonella sp. bacteria expressed as mpn per four grams of total solids in dry weight basis.

(ii) Records documenting that the temperature was maintained at or above seventy degrees Celsius (one hundred fifty-eight degrees Fahrenheit) or higher for at least thirty minutes throughout the sewage sludge.

(16) Pathogen reduction alternative P-16: equivalent process to further reduce pathogens.

(a) Requirements for achieving pathogen reduction alternative P-16. To achieve alternative P-16, sewage sludge that will be treated to generate biosolids for beneficial use shall be treated in a manner that is equivalent to a process to further reduce pathogens, as determined by the director.

(b) Recordkeeping requirement for pathogen reduction alternative P-16: equivalent process to further reduce pathogens. Both of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Analytical results for density of fecal coliform bacteria expressed as the most probable number (mpn) per gram of total solids in dry weight basis, or the density of Salmonella sp. bacteria expressed as mpn per four grams of total solids in dry weight basis.

(ii) Operating parameters or pathogen levels, as necessary, to demonstrate that the process equivalent to a process to further reduce pathogens has been achieved.

(C) Vector attraction reduction options.

Class B biosolids. In addition to the applicable pathogen reduction requirements and the pollutant concentration limits for metals in this rule, a vector attraction reduction option in accordance with paragraphs (C)(1) to (C)(10) of this rule shall be met in order to achieve class B biosolids.

Exceptional quality biosolids. In addition to the applicable pathogen reduction requirements and the pollutant concentration limits for metals in this rule, a vector attraction reduction option in accordance with paragraphs (C)(1) to (C)(8) of this rule shall be met after or at the same time as meeting pathogen reduction requirements in paragraphs (B)(8) to (B)(16) of this rule to achieve exceptional quality biosolids.

(1) Vector attraction reduction option VAR-1: thirty-eight per cent volatile solids reduction.

(a) Requirements for achieving vector attraction reduction option VAR-1: thirty-eight per cent volatile solids reduction. To achieve option VAR-1, the mass of volatile solids in the sewage sludge shall be reduced by a minimum of thirty-eight per cent.

[Comment: Calculations for determining the volatile solids reduction may be found in "Environmental Regulations and Technology, Control of Pathogens and Vector Attraction in Sewage Sludge."]

(b) Recordkeeping requirements for vector attraction reduction option VAR-1: thirty-eight per cent volatile solids reduction. Both of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) The volatile solids concentration of the raw sewage sludge and the final sewage sludge and the location of each sample taken.

(ii) The calculations showing that thirty-eight per cent volatile solids reduction was achieved.

(2) Vector attraction reduction option VAR-2: bench scale anaerobic digestion.

(a) Requirements for achieving vector attraction reduction option VAR-2: bench scale anaerobic digestion. When the thirty-eight per cent volatile solids reduction requirement in paragraph (C)(1)(a) of this rule cannot be met for an anaerobically digested sewage sludge, vector attraction reduction can be demonstrated by both of the following:

(i) Digesting a portion of the previously digested sewage sludge anaerobically in the laboratory in a bench scale unit for at least forty additional days at a temperature between thirty and thirty-seven degrees Celsius (eighty-six to ninety-eight degrees Fahrenheit).

(ii) Showing that at the end of the forty days the volatile solids in the sewage sludge at the beginning of that period is reduced by less than seventeen per cent.

(b) Recordkeeping requirements for vector attraction reduction option VAR-2: bench scale anaerobic digestion. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) A description of the bench scale digester.

(ii) The time in days that the sample was further digested in the bench scale digester.

(iii) Daily temperature records.

(iv) The volatile solids concentration of the sewage sludge before and after the bench scale digestion.

(3) Vector attraction reduction option VAR-3: bench scale aerobic digestion.

(a) Requirements for achieving vector attraction reduction option VAR-3: bench scale aerobic digestion. When the thirty-eight per cent volatile solids reduction requirement in paragraph (C)(1)(a) of this rule cannot be met for an aerobically digested sewage sludge, vector attraction reduction can be demonstrated by both of the following:

(i) Digesting a portion of the previously digested sewage sludge that has a per cent solids of two per cent or less aerobically in the laboratory in a bench-scale unit for thirty additional days at twenty degrees Celsius (sixty-eight degrees Fahrenheit).

(ii) Showing that at the end of the thirty days the volatile solids in the sewage sludge at the beginning of that period is reduced by less than fifteen per cent.

(b) Recordkeeping requirements for vector attraction reduction option VAR-3: bench scale aerobic digestion. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) A description of the bench scale digester.

(ii) The time in days that the sample was further digested in the bench scale digester.

(iii) Daily temperature records.

(iv) The volatile solids concentration of the sewage sludge before and after the bench scale digestion.

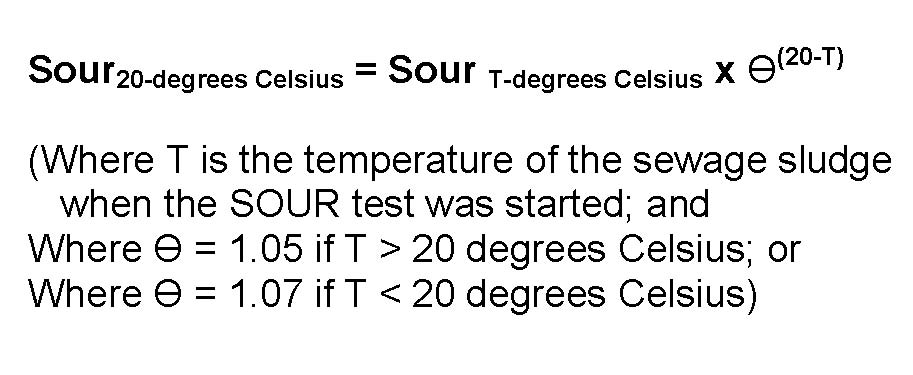

(4) Vector attraction reduction option VAR-4: specific oxygen uptake rate (SOUR) test.

(a) Requirements for achieving vector attraction reduction option VAR-4: specific oxygen uptake rate (SOUR) test. To achieve option VAR-4, the specific oxygen uptake rate for sewage sludge that is treated in an aerobic process at temperatures between ten and thirty degrees Celsius (between fifty and eighty-six degrees Fahrenheit), shall be equal to or less than 1.5 milligrams of oxygen per hour per gram of total solids (dry weight basis) at a temperature of twenty degrees Celsius (sixty-eight degrees Fahrenheit). The temperature of the sewage sludge to be tested shall be maintained at the same temperature as it was in the digester.

(b) SOUR testing shall be conducted in accordance with the standard operating procedure developed under paragraph (C) of rule 3745-40-09 of the Administrative Code. The standard operating procedure for SOUR testing shall take into account the variability in flow rates and performance of the digester. SOUR tests shall be run routinely so that sufficient data are available to indicate average performance. To compensate for variability the arithmetic mean of a minimum of seven successive SOUR tests taken over a two-week period shall give a SOUR of less than or equal to 1.5 milligrams of oxygen per hour per gram of total solids. At a minimum, SOUR testing shall be completed at the frequency required by table B-1 of rule 3745-40-09 of the Administrative Code.

(c) Recordkeeping requirements for vector attraction reduction option VAR-4: specific oxygen uptake rate (SOUR) test. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Dissolved oxygen readings for each sewage sludge sample taken every minute over a fifteen-minute interval.

(ii) Calculations and temperature records showing that each test was corrected to twenty degrees Celsius (sixty-eight degrees Fahrenheit).

[Comment: To adjust the specific oxygen uptake rate to twenty degrees Celsius, use the following equation:]

(iii) Total solids for the sewage sludge sample.

(iv) The SOUR calculations for each test.

[Comment: A SOUR calculation worksheet is available online at: http://epa.ohio.gov/dsw/sludge/biosolid.aspx#137944357-compliance-tools]

(5) Vector attraction reduction option VAR-5: aerobic process time and temperature treatment.

(a) Requirements for achieving vector attraction reduction option VAR-5: aerobic process time and temperature regime. Sewage sludge shall be treated in an aerobic process for fourteen days or longer. During that time, the temperature of the sewage sludge shall be higher than forty degrees Celsius (one hundred four degrees Fahrenheit) and the average temperature of the sewage sludge shall be higher than forty-five degrees Celsius (one hundred thirteen degrees Fahrenheit).

(b) Recordkeeping requirements for vector attraction reduction option VAR-5: aerobic process time and temperature regime. Both of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) The sewage sludge detention time in the aerobic digester or composting process.

(ii) Temperature records showing that the average temperature was above forty-five degrees Celsius (one hundred thirteen degrees Fahrenheit) and the minimum temperature was above forty degrees Celsius (one hundred four degrees Fahrenheit) for fourteen consecutive days.

(6) Vector attraction reduction option VAR-6: lime treatment.

(a) Requirements for achieving vector attraction reduction option VAR-6: lime treatment. The pH of sewage sludge shall be raised to twelve or higher by lime addition and, without the addition of more lime, shall remain at twelve or higher for two hours and then remain at 11.5 or higher for an additional twenty-two hours.

(b) Recordkeeping requirements for vector attraction reduction option VAR-6: lime treatment. All of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) A narrative description of how the pH was monitored throughout the material for the applicable time period.

(ii) Records indicating that the pH was maintained at or above twelve for two hours and at or above 11.5 for an additional twenty-two hours.

(iii) The number of dry tons of the lime material that was added.

(7) Vector attraction reduction option VAR-7: greater than or equal to seventy-five per cent solids.

(a) Requirements for achieving vector attraction reduction option VAR-7: greater than or equal to seventy-five per cent solids. The per cent solids of sewage sludge that does not contain unstabilized solids generated in a primary wastewater treatment process shall be equal to or greater than seventy-five per cent based on the per cent solids and total solids prior to mixing with other materials.

(b) Recordkeeping requirements for vector attraction reduction option VAR-7: greater than or equal to seventy-five per cent solids. Both of the following records shall be maintained and submitted to the director or an authorized representative with the annual report:

(i) Results of per cent solids tests.

(ii) Records showing that the sewage sludge has been stabilized.

(8) Vector attraction reduction option VAR-8: greater than or equal to ninety per cent solids.

(a) Requirements for achieving vector attraction reduction option VAR-8: greater than or equal to ninety per cent solids. The per cent solids of sewage sludge that contains unstabilized solids generated in a primary wastewater treatment process shall be equal to or greater than ninety per cent based on the per cent solids and total solids prior to mixing with other materials until the biosolids are beneficially used. Measures shall be taken to prevent odors and proper storage shall be provided to avoid a decrease in per cent solids.

(b) Recordkeeping requirements for vector attraction reduction option VAR-8: greater than or equal to ninety per cent solids. The results of the per cent solids tests on a dry weight basis shall be maintained and submitted to the director or an authorized representative with the annual report.

(9) Vector attraction reduction option VAR-9: biosolids are injected below the surface of the authorized beneficial use site.

(a) Requirements for achieving vector attraction option VAR-9: biosolids are injected below the surface of the authorized beneficial use site. Biosolids shall be injected below the surface of the authorized beneficial use site, where no significant amount of biosolids shall be present on the surface of the authorized beneficial use site within one hour after the sewage sludge is injected.

(b) Recordkeeping requirements for vector attraction reduction option VAR-9: biosolids are injected below the surface of the authorized beneficial use site. The certification statement, as required by rule 3745-40-09 of the Administrative Code, from the beneficial user shall be maintained and submitted to the director or an authorized representative with the annual report.

(10) Vector attraction reduction option VAR-10: immediate incorporation of biosolids.

(a) Requirements for vector attraction reduction option VAR-10: immediate incorporation of biosolids. Biosolids shall be incorporated into the soil within six hours of delivery to the authorized beneficial use site, unless otherwise specified by the director.

(b) Recordkeeping requirements for vector attraction reduction option VAR-10: immediate incorporation of biosolids. The certification statement from the beneficial user shall be maintained and submitted to the director or an authorized representative with the annual report.

(D) Metals concentration limits.

(1) No person shall beneficially use biosolids if any monitoring result indicates that a pollutant concentration exceeds the pollutant ceiling concentration listed in table D-1 of this rule.

[Comment: If more than one monitoring event occurs for the pollutants listed in table D-1 of this rule then all monitoring results must show pollutant levels below the pollutant ceiling concentrations listed in table D-1 of this rule. Monitoring results cannot be averaged to show that pollutant levels are below the pollutant ceiling concentrations listed in table D-1 of this rule.]

(2) If a monitoring result indicates that a pollutant exceeds the pollutant ceiling concentrations listed in table D-1 of this rule, a permittee shall either dispose of the sewage sludge within a landfill or return the sewage sludge to the initial stage of the sewage sludge treatment train. If the permittee returns the sewage sludge to the sewage sludge treatment train, monitoring shall be repeated and the results must indicate that pollutants do not exceed the pollutant ceiling concentrations listed in table D-1 of this rule before biosolids are removed from the treatment works for beneficial use.

(3) No person shall beneficially use biosolids at an authorized beneficial use site subject to the cumulative pollutant loading rates established in table D-2 of this rule if any of the cumulative pollutant loading rates in table D-2 of this rule have been reached at the authorized beneficial use site.

(4) The pollutant ceiling concentrations, cumulative pollutant loading rates, and pollutant reporting period average concentrations for biosolids shall, as applicable, not exceed the concentrations listed in table D-1, table D-2 and table D-3 of this rule or as required by 40 C.F.R. part 503.

(5) Before class B biosolids subject to the cumulative pollutant loading rates in this rule are applied at an authorized beneficial use site in Ohio, the person who proposes to beneficially use the class B biosolids shall contact the Ohio environmental protection agency division of surface water to determine whether class B biosolids subject to the cumulative pollutant loading rates in this rule have been beneficially used at the authorized beneficial use site since July 20, 1993.

(a) If beneficial use of class B biosolids subject to the cumulative pollutant loading rates has not occurred since July 20, 1993, the cumulative amount for each pollutant listed in this rule may be applied at the authorized beneficial use site in accordance with this chapter.

(b) If class B biosolids subject to the cumulative pollutant loading rates have been beneficially used at the authorized beneficial use site since July 20, 1993, and the cumulative amount of each pollutant beneficially used at the authorized beneficial use site since that date is known, the cumulative amount of each pollutant applied at the authorized beneficial use site shall be used to determine the additional amount of each pollutant that can be applied at the authorized beneficial use site in accordance with this chapter.

(c) If class B biosolids subject to the cumulative pollutant loading rates have been beneficially used at the authorized beneficial use site since July 20, 1993, and the cumulative amount of each pollutant applied at the authorized beneficial use site since that date is not known, an additional amount of each pollutant shall not be applied at the authorized beneficial use site.

(6) Any person who beneficially uses class B biosolids subject to the cumulative pollutant loading rates in this rule at an authorized beneficial use site in Ohio shall provide written notice to the appropriate Ohio environmental protection agency district office prior to initial beneficial use of class B biosolids at the authorized beneficial use site. The Ohio environmental protection agency shall retain and provide access to the notice. The notice shall include both of the following:

(a) The location of the authorized beneficial use site by either street address or latitude and longitude of the center of the beneficial use site.

(b) The name, address, telephone number and NPDES permit number of the generator of the class B biosolids.

| Pollutant | Pollutant ceiling concentration limit (milligrams per kilogram dry weight basis) |

| Arsenic | 75 |

| Cadmium | 85 |

| Copper | 4300 |

| Lead | 840 |

| Mercury | 57 |

| Molybdenum | 75 |

| Nickel | 420 |

| Selenium | 100 |

| Zinc | 7500 |

| Pollutant | Pollutant cumulative pollutant load rates (pounds per acre) |

| Arsenic | 36.6 |

| Cadmium | 34.8 |

| Copper | 1339.9 |

| Lead | 267.9 |

| Mercury | 15.2 |

| Nickel | 375.1 |

| Selenium | 89.3 |

| Zinc | 2500.4 |

| Pollutant | Pollutant reporting period average concentration limit (milligrams per kilogram dry weight basis) |

| Arsenic | 41 |

| Cadmium | 39 |

| Copper | 1500 |

| Lead | 300 |

| Mercury | 17 |

| Nickel | 420 |

| Selenium | 100 |

| Zinc | 2800 |